All Aspects of Aluminium

Aluminium (Al), a silver-coloured metal with atomic number 13 and a density of 2.70 g/cm cubed, is the third most abundant element on earth after silicon and oxygen. Aluminium, which does not occur in pure form in nature, but in oxide and silicate compounds, is an indispensable raw material for industries with its lightweight, durable, corrosion-resistant, easily processable, recyclable and high conductivity properties. The need for aluminium, which is used extensively in the aerospace, aircraft, defence, automotive, electrical, electronics, food, beverage, packaging, construction and consumer products sectors, is increasing.

Aluminum Production

Aluminium production takes place in two stages: "primary" and "secondary". Primary production comes from bauxite ore and secondary production comes from the recycling of scrap aluminium. While 90 percent of the world's bauxite reserves are used in aluminium production, 10 percent is used in cement, chemical, refractory and abrasive industries. Between 30 and 60 percent of bauxite ore, which is considered to be operable in the industry, contains aluminium.

Bayer Method is Used

Pure aluminium is obtained from bauxite ore by different techniques. One of these applications is the Bayer Method developed by German chemist Carl Josef Bayer in 1887. In the first step of this method, which is widely preferred in the aluminium industry, oxide (alumina) is produced from bauxite ore. In the second step, pure aluminium is produced from alumina by electrolysis under high pressure and temperature.

Classification According to Production MethodsThe classification of aluminium products is based on how they are shaped and manufactured. Aluminium products can be classified according to their production methods as follows:

Casting Products: It is the process of pouring aluminium-silica alloy into moulds after melting (with applications such as pressure casting, sand casting, coil). Aluminium castings, which are lightweight and have high strength, are preferred in many fields, primarily in the aviation and automotive industries.

Extrusion Products: Extruded products, which have a wide range of usage opportunities with the benefits they provide, are produced by heating aluminium and passing it through moulds and changing its cross-sections. (Example: Profile bars, pipe and pipe systems, frames, etc.) Extruded products, which stand out with their wide product range, are preferred in many areas such as space vehicles, automotive, train, food, electricity, chemistry, facade cladding, machinery and equipment.

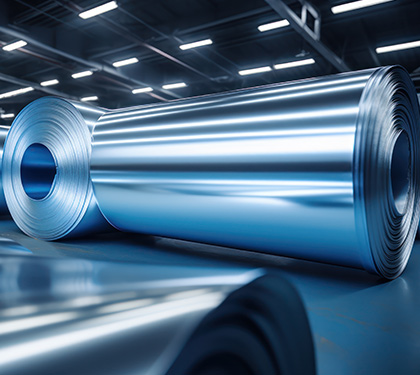

Sheet and Plate Products: Aluminium is obtained by pressing and rolling aluminium material under intense pressure into flat sheets or plates. Lightweight, corrosion resistant, easy to shape, easy to install and easy to maintain, they are frequently required in industrial, agricultural, household and production applications.

Forged Products: It is produced by heating aluminium and forging it into the desired shape. Due to its light, durable and high corrosion resistance, it is used in many industrial processes, especially in the aviation, defence, automotive, electrical-electromechanical and medical sectors.

Welding Types: It is produced by joining aluminium parts after melting them under high heat. Aluminium welding materials, which are important parts of the aviation, automotive, marine and construction industries, include TIG rods, MIG wire and alloy welding wire.

Areas of Use of Aluminium

As in the rest of the world, aluminium is the most preferred base metal after iron and steel in Turkey. Aluminium is preferred for lighter, robust, efficient, long-lasting and economical products. As the population increases and technology advances, aluminium is becoming more and more present in all areas of life with its many advantages (light, robust, efficient, long-lasting). Aluminium is the main raw material of many sectors such as construction, transportation, chemistry, food, electricity-electronics, machinery-equipment and metal.

World Aluminium ReservesAluminium is abundant in nature. However, metal aluminium is obtained from bauxite ore. According to the report (2018) prepared by experts from Mineral Research and Exploration (MTA), the world's bauxite reserves total 55-75 billion tonnes.

Approximately 30 billion tonnes of this is operable reserves. Approximately 275-300 million tonnes of bauxite and 120-130 million tonnes of alumina are produced annually in the world. There has been an increase in aluminium raw material production over the years. The countries with the richest bauxite reserves in the world are as follows:

- Guinea (7.4 billion tonnes/25 per cent)

- Australia (6 billion tonnes/20 per cent)

- Vietnam (3.7 billion tonnes/12 percent)

- Brazil (2.6 billion tonnes/9 percent)

- Jamaica (2 billion tonnes/7 percent)

- Indonesia and China (1 billion tonnes/percent 3

- Guyana (850 million tonnes / 3 percent)

- India (830 million tonnes (3 percent)

- Russia (500 million tonnes / 2 percent)

- Other countries (3.2 billion tonnes/ 11 percent)

According to the data in MTA's report; Turkey's total visible/prospective/possible reserves are 422 million tonnes. The operable reserve is 63 million tonnes. In Konya Seydisehir and Antalya Akseki field, where the largest bauxite reserves are located, there are 36.5 million tonnes of total reserves and 31 million tonnes of operable reserves. Bauxite deposits are also found in Tufanbeyli (Saimbeyli), Zonguldak (Kokaksu), Islahiye (Payas), Muğla (Milas), Isparta (Yalvaç), Alanya and Bolkardağı regions. Turkey's bauxite reserves are sufficient for many years. Bauxite used in primary aluminium production is supplied from domestic resources, while refractory bauxite needed by the industry is met through imports.