What is Aluminum Extrusion Profile? What are the Features and Areas of Usage?

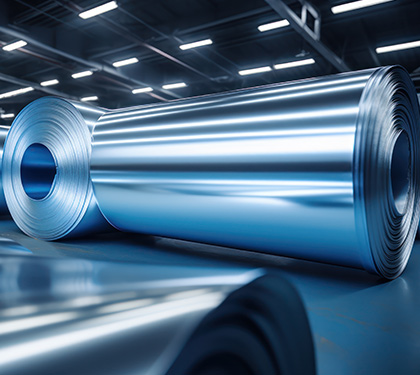

Aluminum is used in many industrial areas such as automotive, construction, electronics, electronics, white goods, furniture and solar energy with its lightweight, durable, elastic, corrosion-resistant and electrically conductive properties. Extrusion is an economical manufacturing process. This method, applied in industry, is to produce metal in different shapes and sizes by passing it through a mold.

What is Aluminum Extrusion?

Aluminum extrusion takes place when high-temperature aluminum tickets are passed through an extrusion press and inserted into a mold. With these presses, which are usually hydraulically or mechanically operated, aluminum pieces are passed through a protrusion of a certain shape and size. The extrusion process turns the aluminum into profiles in various shapes such as boxes, rods, L- and T-shaped or ovals.

What are the Stages of Aluminum Extrusion?

First, a mold made of steel or cast aluminum material suitable for the designed profile is prepared. Then, the aluminum tickets in the form of raw material are heated to approximately 350-500 degrees.

This prevents the mold and the material from sticking to each other and makes it easier to shape. The heated aluminum raw material is placed in the feeding part of the extrusion press and the profile is obtained by passing through the press die with the pressure applied.

The formed aluminum profile is cooled with air and water to maintain its properties. The cooled profile is cut to the desired lengths and, if necessary, subjected to processes such as drilling, surface treatment or cross-sectional shaping.

In Which Areas Are Aluminum Extrusion Profiles Used?

Aluminum extrusion profiles obtained by special shaping and processing methods have wide usage opportunities due to their advantages.

Designed to meet aesthetic and functional requirements, aluminum extrusion profiles are preferred in many areas from the energy and automotive industry to the construction and furniture sector, from electronics to transportation vehicles.

What are the Features of Aluminum Extrusion Profiles?

The features of aluminum profiles produced by shaping with special methods in the extrusion die can be listed as follows:

• Aluminum extrusion profiles are very durable and lightweight. Therefore, transportation and assembly processes are easy.

• Aluminum extrusion profiles are resistant to corrosion. Therefore, it has a robust structure against hot or cold weather conditions and chemical effects.

• Aluminum extrusion profiles are rustproof and rotproof. This means lower cost savings in the long term.

• Extruded profiles are easy to process and can be designed in different shapes and sizes. This provides an aesthetic, attractive and modern appearance for applications.

• Aluminum extrusion profiles, which are good heat and electricity conductors, manage heat changes effectively. For this reason, it is an ideal option for electrical operations.

• Aluminum extrusion profiles are environmentally friendly with their recyclable properties. In this respect, they support the effective use of resources.